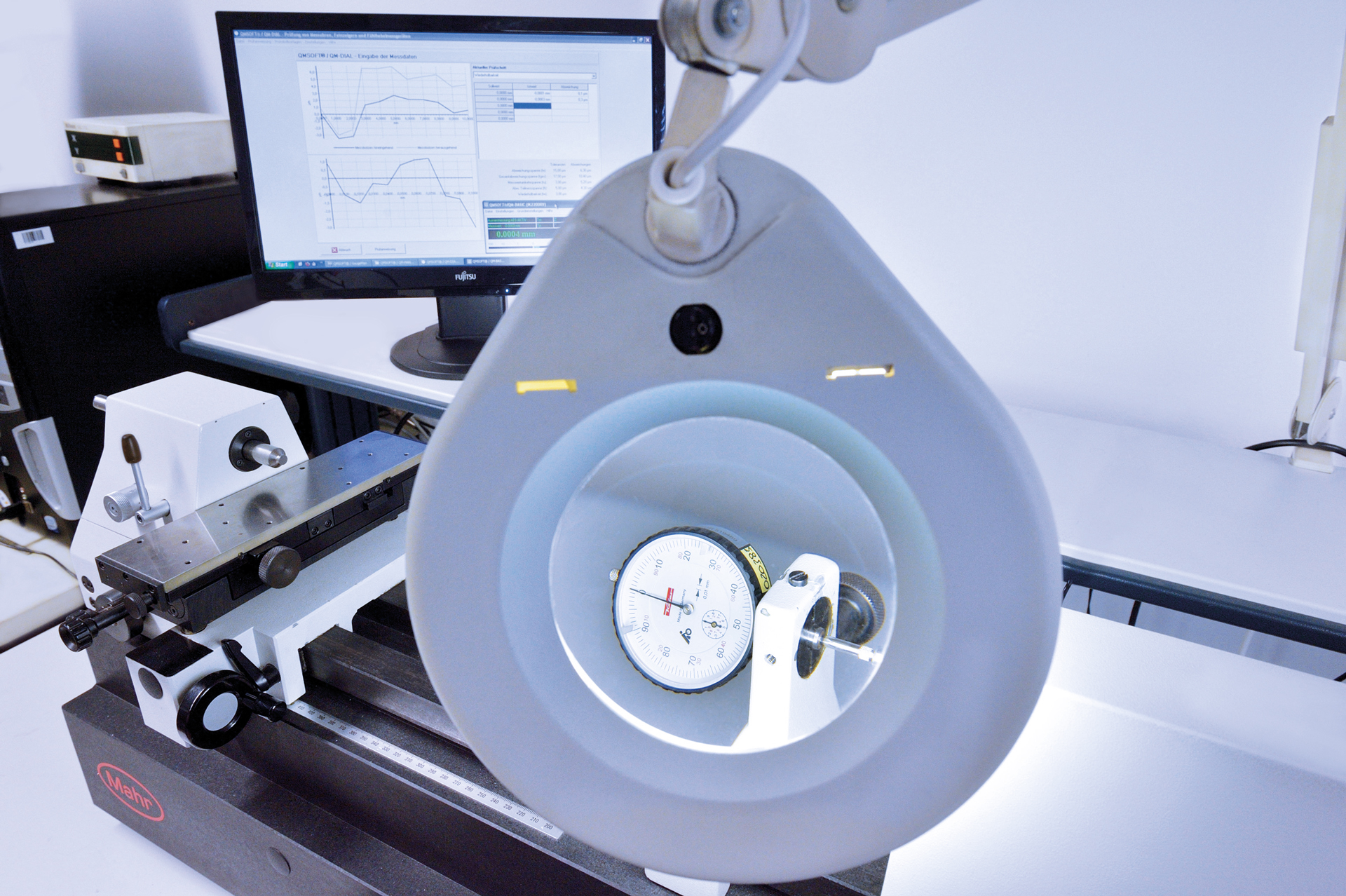

As one of the largest independent calibration laboratories in Germany, esz AG is the ideal calibration service provider. Our full-service offer enables your company to calibrate, maintain, service and repair its entire fleet of devices from a single source. We offer you DIN EN ISO/IEC 17025:2018 DAkkS accredited calibrations with the accreditation symbol (DAkkS calibrations). To ensure that your measurements are internationally comparable, precise and repeatable, you need certainty and the highest level of quality. With over 200 accredited measurands and measuring ranges, esz AG is one of the leading laboratories in Europe. Thus, you can rely on one of the most efficient calibration services. Regular calibrations are the only way to test your measuring devices for full functionality, determine measurement deviations and avoid measurement errors. Because mistakes can be expensive: So prevent possible product liability risks by carrying out regular calibrations. Register now Benefit from the advantages of personal online access to over 30,000 measuring devices, route booking and much more! Already have an account? Then please register here. With seven accredited locations in Germany, Austria and Hungary, esz AG calibration & metrology is your competent and efficient partner for calibration and test equipment management as well as maintenance, adjustment and repair. We work independently of manufacturers and offer you optimum service and greater security. Electrical calibrations are used in almost all areas of research, development, industry, technology, medicine, food technology and the environment. They play a key role in metrology, as most quantities are converted into electrical signals at the sensor. The laboratory areas for pressure, scales/weights (mass), force, vibration, shock, acceleration, flow and torque cover further measurement areas of industrial technology. How big, how heavy, how strong, how fast? esz answers these questions with the utmost precision. In the field of temperature and environmental measurement variables, esz AG technicians work with temperature control equipment from -80°C to +1210°C. We achieve the smallest measurement uncertainties from 20 mK. We even achieve 15 mK at the water triple point. The metrological evaluation and calibration of power meters, light sources, opacity filters, illuminance, attenuators and OTDRs has become increasingly important in automotive engineering, communications technology, medical technology, motor vehicles and consumer electronics. For calibrations up to 67 GHz, the esz AG high-frequency laboratory is one of the best-equipped laboratories in Europe. With the help of our reference devices, the HF standards for use in various coaxial systems are traced back and calibrated with the highest accuracy. Dimensional quantities round off the business field of industrial calibration for customers from mechanical engineering, vehicle and aircraft construction in all sectors. Our technicians calibrate at reference conditions of 20 °C ± 1 K on state-of-the-art machines from the measuring technology supplier Mahr. The automotive industry uses a wide range of test equipment in workshops, inspection centres, test centres and test bases. esz AG fulfils the requirements profile of the DAkkS for accredited calibrations, e.g. of brake testers, headlight testers and exhaust gas measuring devices. For anyone who uses their measuring devices on a daily basis, every day of downtime means valuable time lost. esz AG’s mobile calibration service performs calibration on site, whether in production, development or in the test field, with minimal downtime. Service With the esz AG collection and delivery service, your sensitive test equipment is always in safe hands. Transport is carried out in protective devices, by trained drivers and directly to and from the calibration laboratory. To ensure the consistent quality of products, quality management systems such as the DIN EN ISO 9000/ 9001 family of standards are essential. This standard requires all quality-relevant properties of a product to be tested and traceably calibrated test equipment to be used regularly. Calibration ensures that the measurement results are internationally comparable and that product liability risks remain low – an important prerequisite for competitiveness in the markets of today and tomorrow. The DIN EN ISO 9000 / 9001 family of standards requires the traceable calibration of test equipment. DAkkS-accredited calibration fulfils this requirement unconditionally. These calibration certificates are valid internationally without further proof of traceable measurement results. There are also measurands for which the DAkkS does not offer accreditation. In these cases, ISO calibration offers a fully-fledged alternative. Further information on DAkkS calibrations can be found here. In principle, esz AG calibration & metrology does not differentiate between DAkkS-accredited and ISO calibration in its measurement methods and procedures. DAkkS calibration is usually necessary when companies require it. This procedure has no influence on the traceability of the measured values. Both measured values of the compliant ISO and DAkkS calibration can be displayed equally. Nor do the procedures usually differ in scope, type or care. ISO calibrations are optimised within the framework of quality assurance according to DIN EN ISO 9001ff, are subject to the declaration and QM system of esz AG, DAkkS calibration certificates and procedures are regularly monitored and confirmed by the accreditation body. However, the main difference lies in the recognition of the calibration certificates. ISO calibration is subject to the laboratory’s voluntary commitment to traceability, good laboratory practice, expert measurement uncertainty calculation and conformity to DIN EN ISO/IEC 17025. DAkkS accredited calibration certificates are subject to monitoring by the accreditation body and constant external control. In addition, these are internationally recognised by the multilateral agreement of the ILAC (MRA) and confirmed as proof of origin. The traceability of the measured values contained therein to a national standard therefore does not actually have to be specified in detail; this is guaranteed by the accreditation itself. Form, structure and content are defined and regularly monitored by the accreditation body and thus ensure international conformity with the contents of DIN EN ISO/IEC 17025. In both cases, the selection of the measuring points (if available) is based on national guidelines or DKD guidelines or defined by the customer or specified by the calibration laboratory within the framework of the rules of technology. The official and formal expenses of DAkkS calibration generally lead to increased calibration costs, but also to an internationally valid calibration certificate, which makes the accuracy specifications of measuring devices traceable with high precision based on the individual results. In order to be able to offer the most comprehensive service possible, esz AG has invested continuously in recent years. As the largest independent calibration laboratory in Germany, the company is therefore able to calibrate most of the measurement parameters required by industry in its own laboratories. Whether pressure, temperature, torque, length measurement technology, low-frequency or high-frequency measured variables – esz AG acts quickly and reliably. Special devices, e.g. from the medical, fibre optic and laser technology or the aviation industry, are also in good hands in the laboratories. The benefit for you: The calibration prices are therefore purely laboratory prices. An esz customer does not have to bear the logistical effort or the costs of a service provider for the distribution of calibrations. Regardless of the manufacturer of the customer’s inventory, the services can be offered from one and the same source. Instead of the time-consuming and expensive process of calibrating specific devices at the manufacturer, time, costs and administrative effort can be saved. The combination of test equipment management and modern Internet technology represents an ideal platform for networking internal quality assurance and external calibration service providers. As the maintenance, comparison and viewing of test equipment data, device status or movement data is often difficult across departments, the use of web modules makes it possible to centrally manage an entire company’s equipment fleet across locations with minimal effort. In addition, the use of purchased software products for test equipment management, their license problems, maintenance and distribution is no longer necessary. The one-time provision of all test equipment data in digital form means that database access is password-protected via the calibration service’s web server. In addition, changes to the data status, download of current calibration certificates, history evaluations or due date lists are available at any time. Together with an interface for data exchange, esz AG has also implemented online access to the processing status of calibration orders. Full access to all calibration, asset and status information is now possible in real time. You can find out more about test equipment management here. At esz AG, calibration certificates without an accreditation symbol (ISO certificates) also always comply with the requirements of DIN EN ISO/IEC 17025 (sections 7.8.2 and 7.8.4). Basic conformity can be checked quickly using the applicable requirements: Since the purchase of new devices often means high investments, the question always arises as to whether a repair makes economic sense when measuring devices become defective due to overload or wear and tear. Here esz AG offers an attractive alternative with its repair service. Defective devices from all manufacturers are professionally repaired, checked and, if necessary, subsequently adjusted and, of course, calibrated by experienced technicians. This restores the functionality of the devices and the user continues to receive reliable measured values. For the customer, repair offers the advantage of lower administrative costs. Instead of having to send different devices to different companies, esz AG is the ideal partner for the entire measuring device service. Together with the calibration laboratory, this results in a unique contact point on the market, as the entire maintenance of the existing measuring equipment can be carried out from a single source. Defective devices come out of calibration immediately for repair, repaired devices are calibrated in-house. This concentration can therefore eliminate unnecessary logistics costs. Esz AG calibration & metrology even offers attractive services for manufacturers of measuring instruments. Small companies, for example, have high costs to ensure the service of their products or foreign companies often only have sales offices or importers in Germany. Here, esz AG is the strong partner for optimum manufacturer service and can offer excellent cooperation opportunities. This means that repairs are carried out more quickly and shipping to the country of origin is no longer necessary, which has a positive impact on end customer satisfaction.

Minimal risk and maximum quality for your test equipment

Free access to calibration certificates, prices and device search

Our quantities

Electrical quantities

Mechanical quantities

Thermodynamic quantities

Optical quantities

High-frequency quantities

Dimensional quantities

Automotive testing technology

On-site calibration

Logistics Expert

Your benefits

More information

Contact Contact us directly Calibration certificates Download Device search &

price inquiry To the overview